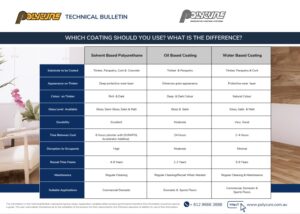

The best coating system will depend upon a number of factors and will vary from job to job. Refer to the table below for further guidelines on which factors must be considered and recommended systems for these situations.

| Solvent Based Polyurethane | Oil Based Coating | Water Based Coating | |

| Substrate to be Coated | Timber, Parquetry, Cork & Concrete | Timber & Parquetry | Timber, Parquetry & Cork |

| Appearance on Timber | Deep protective wear layer | Enhances grain appearance | Protective wear layer |

| Colour on Timber | Rich & Dark | Deep & Dark Colour | Natural Colour |

| Gloss Level Available | Gloss, Semi-Gloss, Satin & Matt | Gloss & Satin | Gloss, Satin & Matt |

| Durability | Excellent | Moderate | Very Good |

| Time Between Coat | 8 Hours (shorter with DURAPOL Accelerator Additive) | 24 Hours | 2-4 Hours |

| Disruption to Occupants | High | Moderate | Minimal |

| Recoat Time Frame | 4-8 Years | 2-3 Years | 5-6 Years |

| Maintenance | Regular Cleaning | Regular Cleaning/Recoat When Needed | Regular Cleaning & Maintenance |

| Suitable Applications | Commercial Domestic | Domestic & Sports Floors | Commercial, Domestic & Sports Floors |